The Matrix® products have wide-ranging applications as replacements of natural raw materials in a variety of industrial cycles, as well as in the modern building industry. Below are the main applications, as used by leading national and international companies and in numerous building projects.

recycling sectors

Cement clinker

Thanks to its conformity to Reach requirements, Matrix® is used, in partial replacement of natural raw materials, as a component of the meal (the finely ground raw material) that is cooked in the cement plant kilns at a temperature of around 1500 °C for the production of clinker.

Matrix® is used as a silica-containing material for the adjustment of meals that are too rich in lime or in addition to natural marl, of which it imitates the composition, although with a lower lime content and a higher silica content.

It is also valued for its flux content, especially aluminium oxide and iron and, because it has already undergone a firing process and partial decarbonation, it also contributes to significantly reducing the overall CO2 amount produced by the process.

Calculations show a reduction of CO2 between 100 and 150 kg per tonne of Matrix used in the cement factory in replacement of 1 tonne of natural marl equivalent.

Premixed concrete

Premixed concrete is a conglomerate obtained by mixing (normally with the addition of additives) cement, large and fine aggregates (gravel, grit, sand) and water.

AGMatrix® is used in premixed concrete as a replacement of natural sand and gravel by leading domestic manufacturers.

AGMatrix carries the CE marking under standard UNI EN 12620, level of attestation of conformity 2+, which is compulsory for aggregates in this sector. Its use in concrete mixtures counts towards the award of various credits under the “Materials and Resources” section of the LEEDâ Certification system, both in the LEEDâ 2009 version and the LEEDâ v4 version.

A closely-linked sector to concrete is that of cement-bound mixtures for road construction. Both AGMatrix and Sand Matrix 0-4 mm can be used successfully in this field, both bearing the CE marking under standard UNI EN 13242.

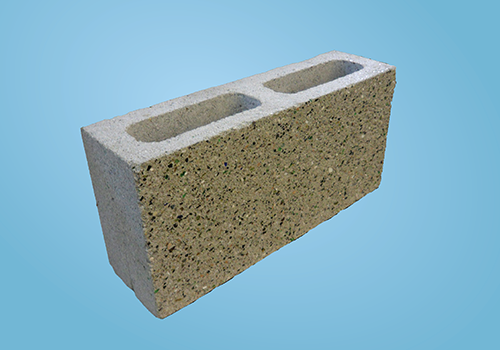

Concrete products

In this sector, both AGMatrix® and Sand Matrix® (in both the 0-4 mm and 2-4 mm grain sizes) are used as aggregates in replacement of sand and gravel to make a variety of products, including concrete anti-slip blocks in all shapes, lane dividers, aggregate concrete blocks, etc.

Bituminous conglomerate

Bituminous conglomerate is a manmade mixture consisting of a variety of aggregates and a bituminous binder. It is generally employed in the construction of drivable surfaces (roads, runways, etc). Aggregates are normally sand, grit and gravel extracted from quarries or deriving from the crushing of rocks. Sand Matrix®, in all its sizes, can be used as an industrial fine aggregate in partial replacement of natural sands in the base and intermediate (binder) layers of asphalt.

A study entrusted to a leading materials testing laboratory (accredited with the Italian Supreme Council of Public Works) on the possible use of Sand Matrix in this sector has been able to demonstrate that all the parameters set out in the general specifications laid down by ANAS (the Italian state-owned company entrusted with the management of roads of national interest) are met.

In recent years, Sand Matrix has found an excellent application as recycled sand for the production of cold-laying bitumen, that product, normally sold in bags, that is used for the repair of potholes on the road surface.

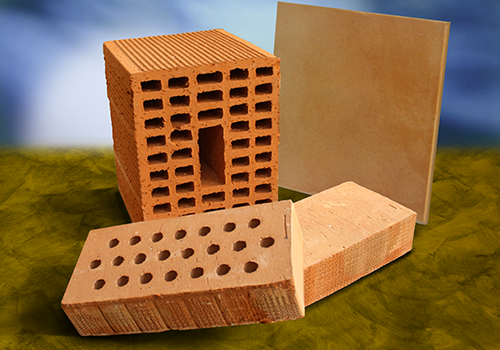

Brick blocks

The main materials used for the production of brick blocks are clay, aggregates and organic fillers and stuffers (sawdust, polystyrene, perlite, etc.). When clay is too plastic, sand-type aggregates need to be added to the mixture so as to diminish water requirements and thus reduce shrinking during the drying and firing phases. As identified in a 2007 study, conducted with the cooperation of the Centro Ceramico di Bologna (Bologna Ceramic Centre), Sand Matrix 0-2 mm is particularly suitable as a filler and is an ideal solution to reduce the quantity of natural sands used in the brick-making industry. Conformity with the REACH Regulation is a prerequisite for access to this product sector.

Ceramic

A cooperation between Officina dell’Ambiente, the University of Modena and Reggio Emilia and a leading manufacturer in the Sassuolo district has allowed to demonstrate that AGMatrix can be successfully used as a replacement of feldspar in glazed technical porcelain stoneware.

Initial laboratory studies are now being followed by pre-industrial application activities, facilitated by the proximity of the Conselice plant to some of the most important tile manufacturers in Italy.

With the necessary technological adjustments, it is possible to replace high percentages of feldspar, with no effect on the mechanical and aesthetical properties of the final product.

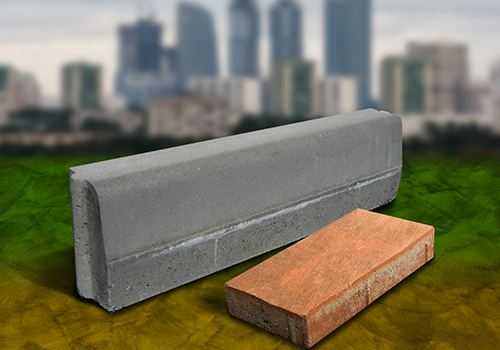

Street furniture

Other possible fields of applications include:

- Concrete anti-slip blocks: a valid alternative to natural stone and bitumen in the paving of external areas.

- Road infrastructure. Possible applications in this sector include different types of lane dividers of very high quality.

Premixed mortars

A constantly-growing sector, in which the product Sand Matrix 0-2 mm – carrying the necessary CE marking as required in accordance with standard UNI EN 13139 (Aggregates for Mortar) – is used. Sand Matrix is used as partial replacement of natural sands for the production of premixed mortars in bags (both standard and fibre-reinforced).