Beyond Sustainability

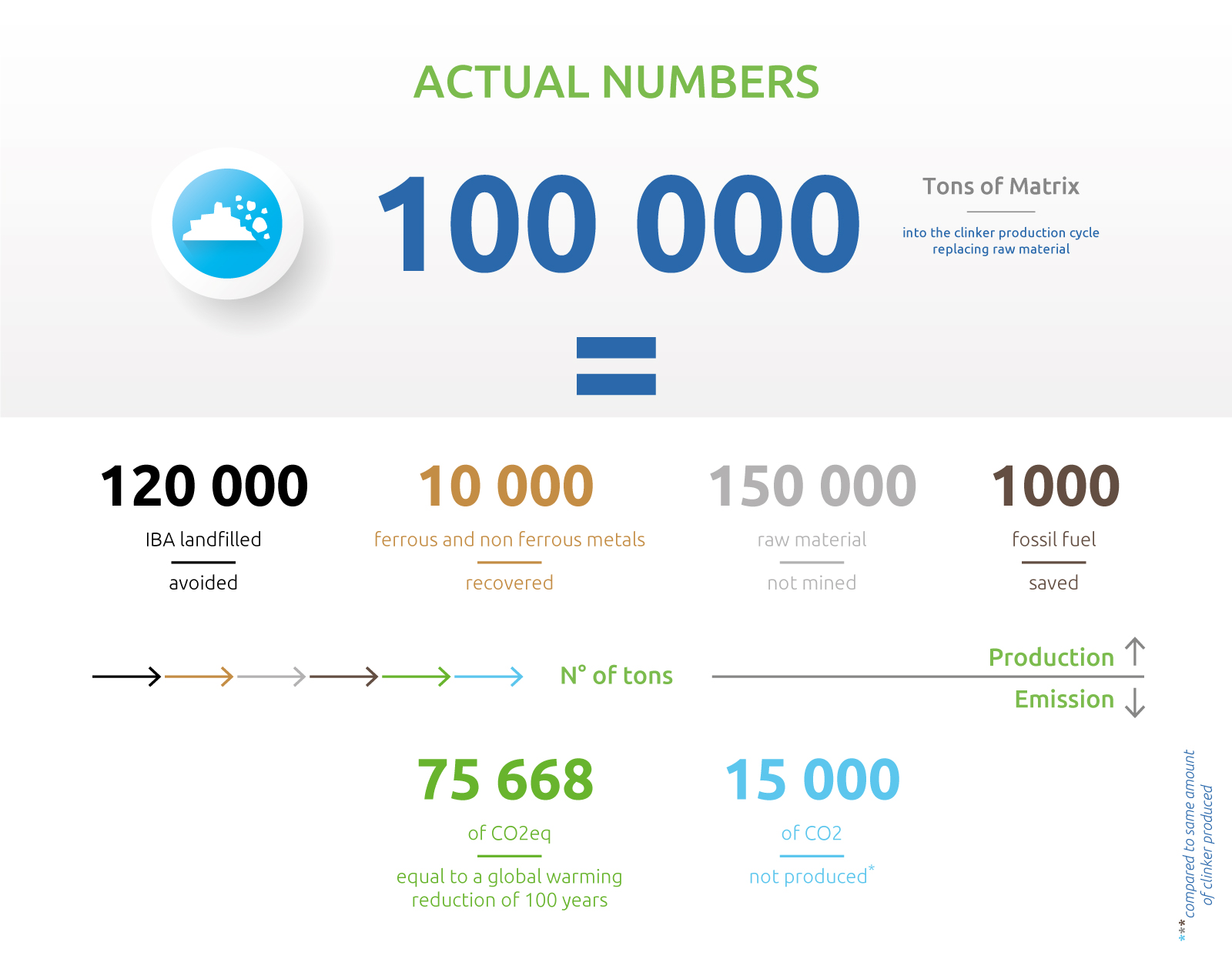

The use of MATRIX® in building materials and products brings objective environmental advantages to end users and stakeholders in general.

The use of MATRIX® in building materials and products brings objective environmental advantages to end users and stakeholders in general.

Circular economy can not ignore the creation of a concrete value

We say ‘objective’ because MATRIX® was subjected to a voluntary in-depth study aimed at establishing actual environmental performance through the analysis of life cycle (LCA – Life Cycle Assessment).

The study made it possible to assess all the environmental impacts associated with the various stages of the life cycle of the MATRIX® products, from cradle to gate.

The in-depth Life Cycle Assessment (LCA) study allowed to rigorously determine the actual performance of the MATRIX® products in terms of a series of environmental aspects, that is of their interaction with the environment, providing end users with accurate reference parameters.

The study was conducted by one of the leading Italian firms in the sector (AMBIENTE ITALIA) and was subsequently validated by certification body Bureau Veritas.

For AGMATRIX® and Sand MATRIX® , the LCA study led to the preparation and validation of the EPD® Certification.

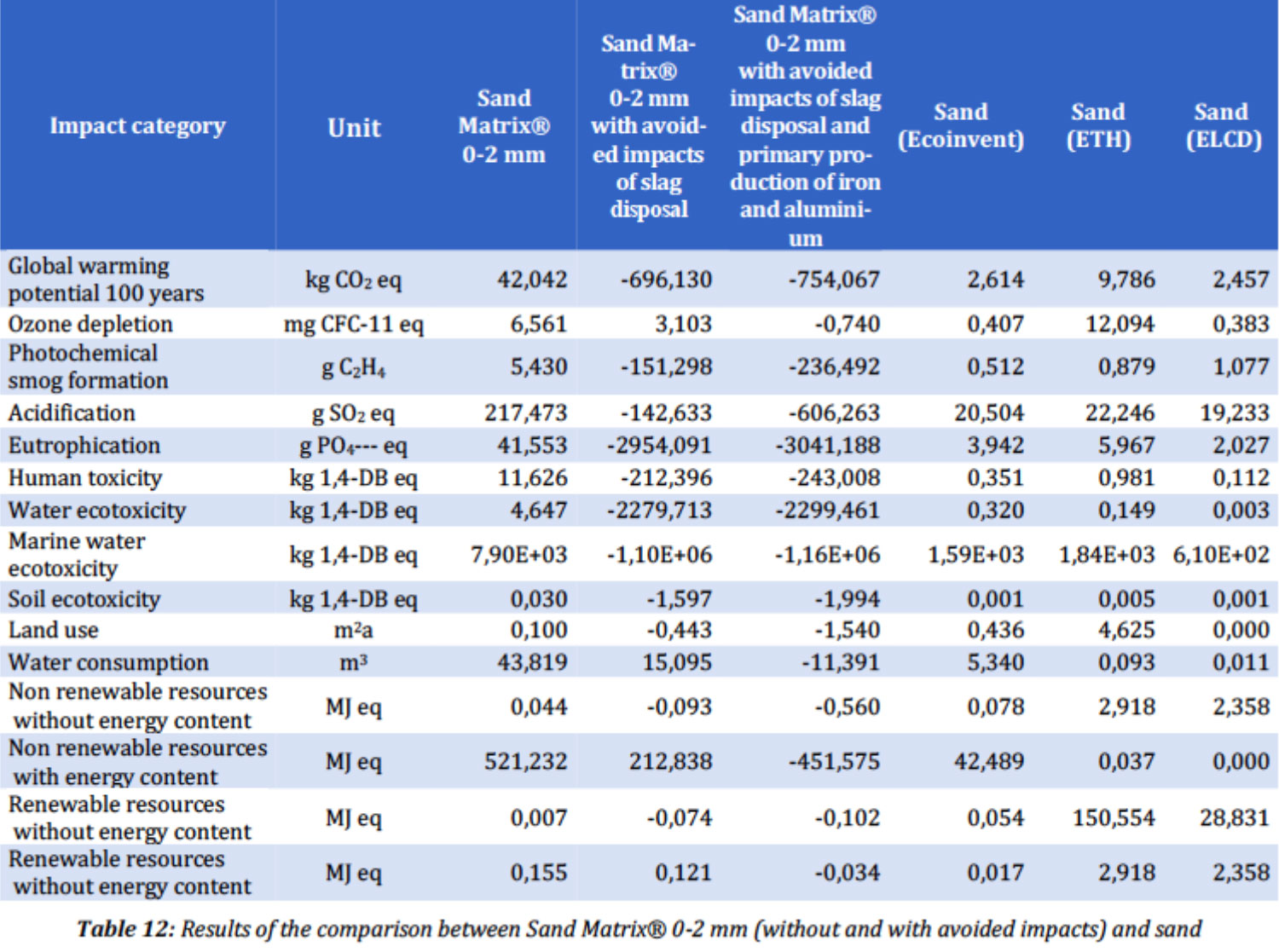

The table below reports the environmental impacts associated with the life cycle of the Matrix products, comparing them with corresponding values for natural sands, as obtained from international databases.

As you can see, Matrix has a lower impact in almost every category of its life cycle, if two undisputable environmental advantages are taken into consideration:

In accordance with the Construction Products Regulation (Regulation 305/2011/EC), all construction products covered by a harmonised technical standard must bear the CE marking and must obligatorily be accompanied by a Declaration of Performance (DoP). The DoP is the key document for construction products, indicating the name of the manufacturer and the information on technical and environmental performances.

Bearing the CE marking, as aggregates to be used in the production of concretes, bituminous conglomerates, mortars and cement-bound mixtures, the MATRIX® products come with specific DoPs, providing comprehensive indications on use to final customers. The standards that are currently covered by our Factory Production Control Certificate are: UNI EN 12620, UI EN 13139, UNI EN 13043, UNI EN 13242.

In order to ensure awareness of use in relation to our products, the DoP indicates the maximum percentage of Matrix that can be used in replacement of natural sands and gravels. This ensures that MATRIX® Inside products and conglomerates are fully compliant with the applicable technical standards and environmental recommendations, with particular reference to the leaching test, and that, at the end of their life cycle, they can be automatically reintroduced into the virtuous cycle of recovery of construction and demolition waste.